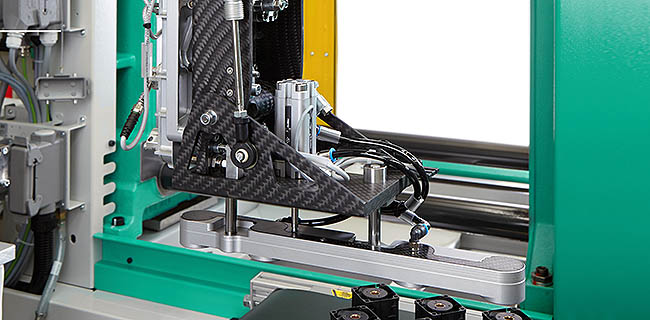

Compact carbon gripper from ARBURG

The comparatively modest additional costs can open up huge potential for enhancing production efficiency. We therefore recommend that each case should be considered in isolation.

|

The main components made from carbon fibber are the basic body and the supporting elements. The two hinged insertion and removal modules are nested in one another. This makes the gripper extremely compact, while also providing more space for functional elements. The insertion module includes a stripper movement for transferring the inserts into the mould.

What you should know

- Weight saving: The lightweight construction with carbon fibber enables the use of a smaller robotic system with smaller load weights

- Cycle time reduction: The gripper is so compact in design that moulds do not have to open as widely

- Lower investment: A smaller mould opening stroke enables the use of smaller injection moulding machines

-

ARBURG spol. s.r.o.

Injection molding machines, injection molding machines, two-component injection moulding, accessories for plastics, production automation, additive...

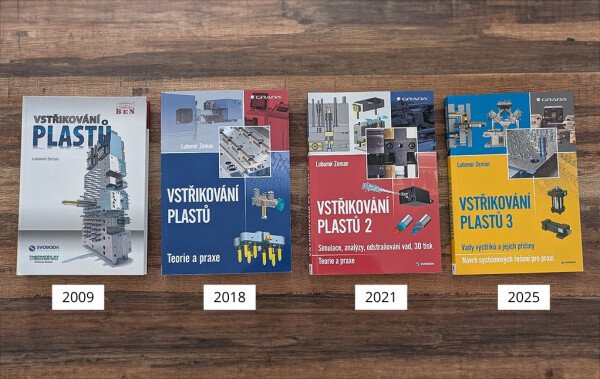

Ing. Lubomír Zeman – Renowned author in the plastics industry publishes his fourth technical book Vstřikování plastů 3

13.6.2025 The fourth technical publication Vstřikování plastů 3 by Ing. Lubomír Zeman follows his earlier successful titles: Vstřikování plastů (2009), Vstřikování plastů 1 (2018), and Vstřikování plastů 2 (2021). The author, regarded as one...

.gif)